21 Dec 2020 - 2020 in Airtightness, brief overview

Just for interest: the best and worst tests of the year in 2020

| Best Air Permeability test | Worst Air Permeability tested New build |

Worst Air Permeability tested Existing |

|

| 1 | 0.319 - timber frame single home | 8.07 - semi detached block with plasterboard | 17.50 - single home, cold in home survey |

| 2 | 0.334 - timber frame single home | 6.70 - timber frame semi-detached | 16.00 - single home, cold in home survey |

| 3 | 0.354 - timber frame single home | 6.31 - timber frame - cold in house survey on new home - yes, really. | 12.83 - single home, cold in home survey |

The three best results are all from the same timber frame supplier. The best we tested that was not from them was q50 of 0.74 m3/hr.m2 on a 2 storey mid terrace house.

20 Nov 2020 - Part L, Part F - airtightness and ventilation: calibration of airtightness works needed to not have mechanical ventilation

The most recent editions of the Building Regulations in Ireland for energy and ventilation, parts L and F respectively, can, when viewed together, leave a builder in a bit of a conundrum.

According to Part F, airtightness for new homes must now be below 5 m3/hr.m2, but if it is less than 3 m3/hr.m2, then a mechanical ventilation system of some description should be installed.

That is the intent, if not the exact wording of the regulations.

Now, for the builder who really does not want to install mechanical ventilation, what does that mean?

It means you must calibrate your build to be between 3 m3/hr.m2 and 5m3/hr.m2.

Thats a tall order.

However, one of our clients who has for the last few years gotten better than 3 m3/hr.m2 on about 90% of their builds has spent some time in 2020 calibrating their process, so that in April when things opened up a bit more after the Covid calamity a number of approaches were tried.

The result? Quite surprising, for us anyway.

The average of the first half of the site, where they were already tricking around with a few things: 3.17 m3/hr.m2

Percent of tests between 3 and 5 m3/hr.m2 = 62%

The average of the second half of the site: 3.43 m3/hr.m2

Percent of tests between 3 and 5 m3/hr.m2 = 84%

As can be seen, they are managing quite well to calibrate the work needed to get between 3 and 5. The problem they will have of course, is what happens to the tests that are below 3 m3/hr.m2 - such as one in June that was 2.98 m3/hr.m2 - who makes the call on that?

21 June 2020 - Ventilation Validation

Greenbuild is one of the first companies in Ireland to be certified by the NSAI for the new Ventilation Validation required by the 2019 Part F revision to the Building Regulations.

The details of the Ventilation Validation scheme are still being ironed out for some of the ventilation types, but for centralised heat recovery (CHRV) and central mechanical extract ventilation (CMEV) the process is fairly straightforward:

- Size the home

- Do a flow rates calculation - Apply the least allowed flow rates criteria in Part F 2019, and see how our calculations compare to the design calculations, select the higher flow rates from the two options. Check these against the commissioning engineers measured flow rates.

- Test flow rates at the registers, using the flow higher flow rates. This is done with a volume based measurement device.

The problem is, the ventilation registers may not always be in a location that allows a flow rate to the checked.

Lesson?

Now, if we cannot reach the unit to validate it, it is quite likely the commissioning engineers also could not reach the unit for correct balancing.

The lesson has to be, if the home is to have ventilation validation performed, all the registers must be in a location that can be reached by a validator (and a balancer!). If you are involved in designing and/or installing ventilation systems, or are to put one in your home please bear this in mind.

So, please:

- No registers in, under or over cupboards or fixed furniture

- No registers so high up that they cannot be reached with a fairly standard step ladder; unless provision is made in advance for some type of scaffold/tower to be in place for the validation procedure.

17 Feb 2020 - The moon in Infra red

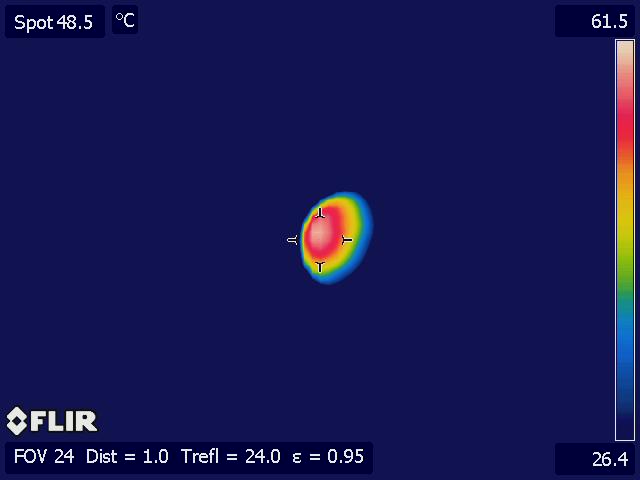

While doing a thermal imaging infra-red survey of a home recently, in the early morning, the moon was brilliant in the sky.

So we took a thermal image of it.

Now, we are no experts in astronomical thermal imaging, but still with the camera on full zoom the image was as we say in these part, a bit of craic!

original full image - moon waning

smoothed out, zoomed in thermogram (thermal image) of moon waning

Note that we did not alter the camera settings for this image

10 Feb 2020 - Airtightness of Blockwork - Part 4

Back in 2013 we had a little series about the airtightness, or not, of concrete blocks. Over the years we have had reason to talk to quite a few people about this. (See previous blog entry from 2013 here).

Today was the first time in a while where we have had to explicitly show a site supervisor why doing a pretest on a building with completed membrane, but incomplete plaster layer on blockwork does not make a lot of sense.

Of course, we did a test as requested, no surprise that the result is over 10 m3/hr.m2, but to be fair that should improve massively once the plaster layer is complete.

The story in the 3 images above is this:

- the left image shows the condition of the wall in overview - well done, tidy blockwork.

- The middle pic shows a typical kind of 'mortar joint' leak as is very common in blockwork.

If we could have counted these in this house, there may have been thousands. - The right hand pic shows a segment of only block taped off loosely. This means there is no mortar joint there, and yet still air leakage.

We could have a bit of fun with numbers and just pretend for fun that the hole size here at the tape is 2cm2.

If so, then the air volume through this 1/2 block in test conditions is 0.01 m3/hr, so the whole block could be 0.02 m3/hr.

If there are about 10 blocks per square meter, and the wall area in this house is 260 m2, allowing even 15% of that to be mortar (a bit high), say we have 220 m2 of blockwork, so that is ca 2200 blocks, which is then about 2200 * 0.02 = 44 m3/hr.

To be fair, the vastly greater proportion of leakages through unplastered blockwork is through the mortar joints - this leakage here directly through the block grain on a very rough sum is only about 1% of the observed leakage rate (but it still counts!)