We love Passive Houses. Please see the Passive House page for some details on airtightness testing of Passive houses.

Greenbuild Blower Door Testing and Airtightness Services

There are two main driving forces behind having an airtightness test undertaken for a premises:

- Because the Building Regulations require it

- Because your building is too cold, or too draughty, and you want to get to the bottom of why that is

There may be noticeable draughts, or in many modern homes and offices there may be just a feeling that it is colder than it should be.

As the climate warms up, warm air infiltration in the summer may also become an issue. Greenbuild offers two related services:

- Air tightness consultancy

- Blower door testing (also called Air Pressure testing or Air leakage testing)

Airtightness

GreenBuild can help you address airtightness at any stage in your build or renovation. The earlier it is factored in, the better.

We can undertake pre-planning information sessions, plan reviews, and site inspections, to ensure that the building is being made as air-tight as possible.

Well Complerted airtight membrane

Blower Door Testing

Blower door testing, or air pressure testing, allows the accurate measurement of air movements through the fabric of your building. Using calibrated equipment in a standardised test manner allows a result which can then be compared against other properties, or earlier tests to the same property.

Greenbuild provides results in Air Changes per hour (n50) and in the regulation m3/(hr.m2)(also called q50 or qe50 in the more recent I.S. EN ISO 9972:2015).

Air changes per hour is the number of times per hour that the entire volume of the heatable part of the building would be changed, while m3/(hr.m2) measures the air leakages relative to the size of the envelope of the building.

Different blower door setups

Whichever unit of measurement is used - the lower the result, the more airtight the building.

During the test, a pressure difference is achieved between inside and outside of 50 Pascals, and the amount of air through the fan is then measured. To arrive at value of the building in use, an approximate result is found by dividing the result at 50 Pascals by 20.

Thus 10 air changes per hour at 50 Pascals is about 0.5 changes at normal conditions.

Greenbuild is audited by NSAI to ensure our testing is in conformity with the required standards, and we have been authorised to test using single fan and multi fan test equipment.

The standards most commonly tested to are I.S. EN ISO 9972:2015 and the older EN 13829:2000.

Locating the leaks

While the pressure test is being undertaken, the opportunity is there to find the leaky areas which are allowing the air through the fabric of the building.

This is normally done simply by hand, or with thermal imaging, thermal anemometry and smoke.

It should be noted that air tightness testing can only check for infiltration air - that is air that comes in via holes and gaps etc.

It does not and cannot really find other draught sources - such as for example where high roof windows create a cold area in the roof and thereby convection currents, or where a ventilation system or ventilation opening is responsible for more air movement than planned.

Smoke

The smoke machine allows leaky spots to be located, particularly around windows and doors. An example of this is to depressurise the house (i.e. extract air from it with the fan) and then, standing outside, blow smoke using a small smoke gun around the window ope. A person on the inside can then locate where the smoke, and thus the air, is entering the house.

Image showing small smoke device in use to locate air leakage route

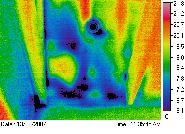

Thermal Imaging

Using thermal imaging - when the house is depressurised then colder outside air traversing the fabric of the building shows up well on the camera, and thus gives away the location of the entrance points into the living space, as well as oftentimes showing up the otherwise hidden route behind the surface. This is possible because, even though the camera does not x-ray the structure, the cold air moving behind the surfaces cool them down, allowing the camera to pick up the pathways.

Images showing the effect on a conservatory ceiling of air infiltration during a pressure test (note that the spotlight in the centre of the image had been turned off by the time the second image was taken)

Thermal Anemometer

Whilst the smoke and thermal imaging camera are excellent for locating the leaks, the thermal anemometer gives an indication of the severity of the leaks. Using the thermal anemometer the air speed is measured at the access points, allowing for comparisons and for the leaks to be prioritised by severity.

Image showing thermal anemometer in use during depressurisation test at 50pa

Greenbuild testing services can be offered as a package or on an individual basis to fully test and document the performance of your property.

Our areas of operation are mostly the Midlands, East and South East of Ireland - Dublin, Wexford, Wicklow, Meath, Kildare, Laois for example, but we can travel where our particular expertise is required, or we may be able to recommend colleagues closer by.

Greenbuild Home Visit Services

If you are cold in your home, we can help!

Much of the cold felt at home in Ireland is due to air movement - drafts and air leaks. We offer various levels of draught testing services from simple walk arounds, with little or no equipment, just an experienced eye, up to full draft inventory with report on how it may be tackled.

Whichever level of service or audit you might be interested in, the aim is to help you find sources of potential heat (and money) savings, and how to prioritise any works that may be needed.

You will find some more detail here.